How To Put Thick Plywood Over A Sub Floor In A Mobile Home

If part of your mobile home renovation process involves installing a new plywood floor over a subfloor, it's imperative that you learn more about the proper approach. In addition, understanding plywood and the types of underlayment you might choose to work with is an important step in the remodeling process.

What Is Plywood?

What Is Plywood?

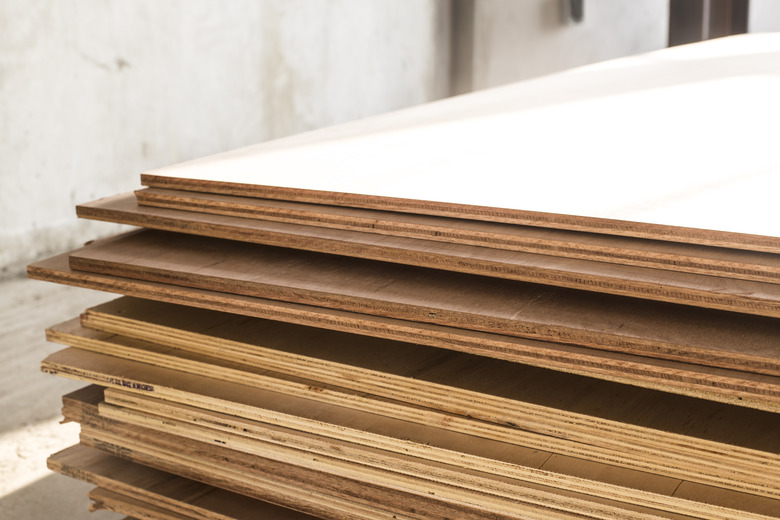

Plywood is made up of several layers of wood veneer glued together with adjacent layers that form a composite substance. It is commonly used beneath a finished floor of some kind, such as laminate, hardwood or even carpeting.

Subfloor is the foundation that you'll find beneath a finished floor. Underneath a wood-based floor, subfloor provides a base upon which you can build (and sometimes in a basement, the subfloor will be made of concrete.

In many cases, plywood serves as a subfloor. This is not always the case in a mobile home, however, where subfloors may be made of lesser-quality particleboard. Mobile home subfloor thickness may be of some concern, and installing plywood over this subfloor can give you a stronger base for your hardwood, laminate or carpeting. Be aware that installing plywood over a subfloor will leave you with an unfinished surface that is exposed; you will almost certainly want to add another layer of flooring before you've completed the job.

Preparing the Subfloor

Preparing the Subfloor

The first step in a renovation project involving your subfloor is to remove all of the furniture from the area where you'll be working. Additionally, if there is a carpet over top of your current subfloor, you'll have to rip that up with all accompanying cushioning or other underlayment material. If you have molding or baseboards, they are also likely in the way of your renovation work and should be temporarily removed.

You'll also have to clean the subfloor so that once you start laying down plywood, you won't run into a mess that could make your flooring uneven. Dirt, debris and other unclean substances can cause your flooring to be uneven. Additionally, if there are any broken planks in your subfloor (or cracks and holes in a concrete subfloor), then you'll want to repair those as well to avoid finding uneven spots again.

Dealing With a Lumpy Floor

Dealing With a Lumpy Floor

One solution if you see bumps in your current subfloor is to take plywood flooring (at least 1/2 inch thick) and place it over the existing planks to help smooth out these uneven patches. Additionally, if your floor has glue that's wearing out or you can just tell that this subfloor has seen better days, then you can always sand it down to remove bumps.

Fixing Any Imperfections

Fixing Any Imperfections

You can easily find the uneven spots in your floor by dropping some marbles or coins and seeing how they roll or scatter. Warped or uneven subfloors can cause significant problems when installing new subfloor or finished floor.

Another common issue is if the plywood board is bowing upward, which can be fixed by removing the warped board and sanding it down with a heaving joist in the uneven areas. For other panels that were inserted incorrectly or that have warped over time, you'll need to shim those panels down. This means you would need to insert thin, wedge-shaped pieces of wood in the low areas to balance everything out.

Different Types of Plywood Subfloors

Different Types of Plywood Subfloors

Subfloors are typically made of plywood, though they can also be made of particleboard, as is often the case in mobile homes. If you are looking to put plywood over a particleboard subfloor, there are a few different types of plywood that you can use for your subfloor. The most common types are oriented strand board (OSB), CDX and tongue and groove.

OSB and CDX Plywood Subfloors

OSB and CDX Plywood Subfloors

OSB is a structural panel that differs from traditional plywood in the sense that it uses wafers that are pressed together with binders to form the panel rather than multiple layers of laminated veneer. This results in a different structure that is not the same as particleboard, though they do seem like they might look or be created in the same way. OSB is the most common type of plywood subfloor.

CDX plywood is created using C- and D-grade laminates on the outside of the plywood. These substances are rather rough and full of many imperfections. This type of plywood, therefore, should ideally be used as subfloor rather than the top layer of a floor. The "X" of CDX is noteworthy because it means the plywood can withstand some exposure, according to EZ Wood Shop, in the same way that OSB plywood can.

Tongue and Groove Plywood Subfloors

Tongue and Groove Plywood Subfloors

Tongue and groove plywood is used in many different types of woodworking. There is a ridge on the edge of plywood where other pieces can fit into that slot, and both OSB and CDX can be found in this style. With these grooves and slots to fit into it, the subfloor will fit well into itself so that it doesn't move or squeak when you walk on it eventually. And with some adhesive, you'll be able to really ensure that the panels in your subfloor don't move at all in a tongue and groove flooring.

Acclimatizing the Wood

Acclimatizing the Wood

Before beginning your plywood installation, you'll want to acclimatize your wood. This allows it to contract and expand naturally (all wood will undergo this process), due to the temperature and moisture level of the room you'll be working in. You'll want to take the plywood from its storage space and leave it in the room where it will be installed so that it can adapt to the new moisture levels and humidity. This is a critical part of the installation process.

Laying Plywood Over Floorboards

Laying Plywood Over Floorboards

Installing plywood underlayment over a subfloor is fairly straightforward. You'll start laying plywood over floorboards by putting a square in the corner and leaving about 1/8 inch between the plywood and the wall. This is because the materials will expand and contract depending on factors like temperature and humidity.

Then, you'll attach the plywood squares to the subfloor with wood screws that are spaced apart every 9 inches. Screwing in the wood screws in a counterclockwise direction will ensure that the screwheads don't stick up from the wood. You'll also avoid tripping on them or ruining clothes and furniture on the exposed screwheads. Additionally, if you have a screw gun, you'll be able to do this part of the job much more easily than screwing by hand.

After this step is complete, you'll continue measuring and cutting all of the pieces of plywood to cover the rest of the floor. Again, you'll want to leave 1/8 inch between each piece of plywood to account for expanding and contracting. Whenever you cut down a piece of plywood, you'll also want to sand down the edges so the wood panels don't stick up at an angle, which could lead to unevenness. You'll continue cutting, sanding, placing the plywood and screwing them down until the entire subfloor area is covered, at which point you can re-install any baseboards or molding you had removed.