What Are The Three Types Of Soldering?

Soldering, similar to welding, is the process of bonding pieces of metal together. You accomplish this by placing a separate alloy, called solder, between the parts to be bonded. Heat the solder with a soldering iron, gun or torch to melt it. As the solder cools, it hardens and forms a bond between the metal pieces. Unlike welding, the metal being bound together is not melted; only the solder melts to create a bond. There are three basic classifications of soldering.

Soft Solder Is Common

Soft Solder Is Common

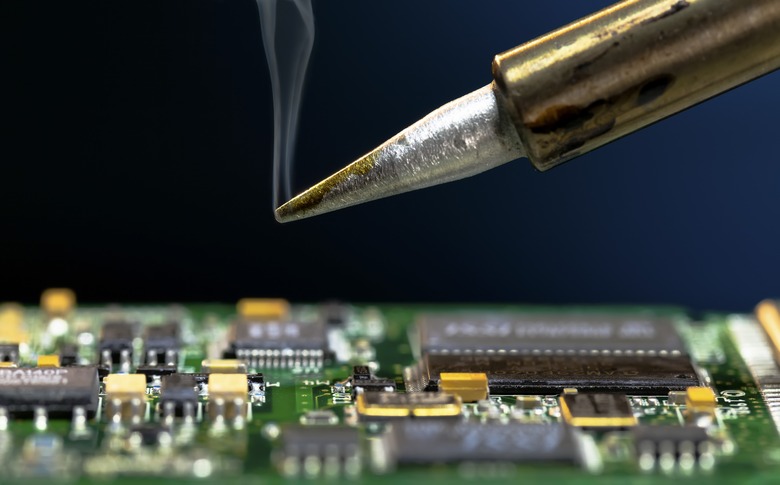

The soft-soldering process is common in the electronics and plumbing industries. This method creates electrical connections and bonds electronic components onto circuit boards. It is also used to join copper pipe and connectors. Solder used in the soft-soldering process for electronics is often made of a mixture of tin and other types of metal. To ensure a tight fit when bonding plumbing, add an acid substance, called flux, to ensure the solder connects the pipes. Soft soldering uses either an electric or gas-powered soldering iron in most cases. The bond created via this method is weaker than the bond created with some other forms of soldering.

Hard Solder is Stronger

Hard Solder is Stronger

Hard soldering creates a stronger bond compared to soft soldering and involves higher temperatures to melt the solder material. This material is normally brass or silver and requires the use of a blowtorch to melt. The metal being bonded, know as the base metal, is heated to a point at which the brass or silver solder melts, creating a strong joint as it cools. In some cases, when someone uses silver as the solder material, hard soldering may be referred to as silver soldering. Although silver melts at a lower temperature compared to brass, it is more expensive. Use hard soldering with silver solder when joining pieces of copper, brass or silver.

Brazing Involves High Temperatures

Brazing Involves High Temperatures

Brazing involves a solder material that melts at a higher temperature compared to soft and hard soldering. Brazing is similar to hard soldering because the pieces of metal being bonded together are heated, but not melted, during the bonding process. Once you have the base metals heated, place solder material, called brazing filler metal, between the surfaces, It instantly melts. The molten filler material bonds the joint between the base metals through a process called capillary action.

Types of Soldering Equipment

Types of Soldering Equipment

Use a soldering iron for intricate soldering of electronic parts and circuit boards. The iron is designed with an end piece shaped like a pencil tip. While soldering, the tip becomes hot and melts the solder. A soldering gun is a larger unit with a handle used to grip the device. Soldering guns have a larger tip compared to an iron, and are designed for bonding larger items together. Use a soldering torch for projects requiring greater amounts of heat to melt the bonding material. Soldering with a torch is common when bonding copper and other types of pipe. It isn't precise enough to handle delicate electronic connections, plus the added heat could damage electronic components.