How To Repair A Weak Flame In A Propane Torch

We may receive a commission on purchases made from links.

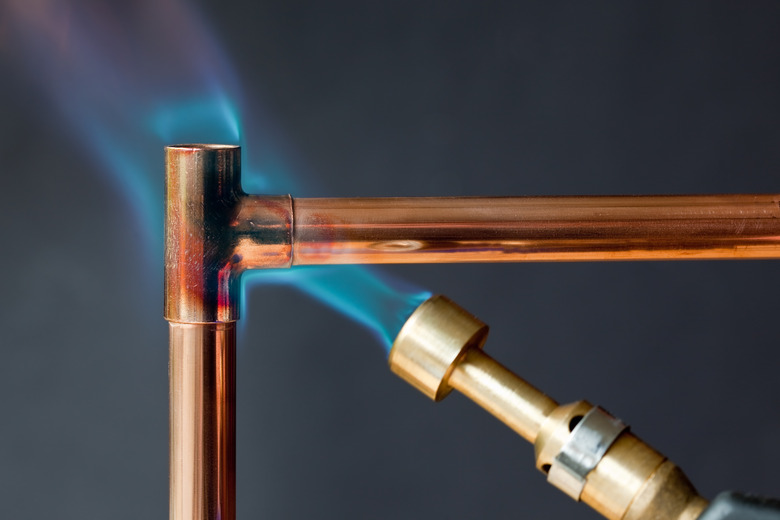

When you think about who uses a propane torch, a plumber immediately comes to mind because it's the go-to tool for soldering copper pipe joints. However, a number of craftspeople and tradespeople use them as well. They're useful for jewelry work, roofers use them to stick together waterproof shingles, woodworkers use them to etch designs, and even landscapers and gardeners can use them to kill weeds.

Bernzomatic is one of the leading manufacturers of propane torches, and when your Bernzomatic torch is not lighting, the usual cause is a blockage in the nozzle. What if the torch lights but only has a weak flame? That will prevent you from using the torch effectively, and again, the cause is usually a blockage. Before you start your Bernzomatic torch repair project, though, there's one important thing to check.

Is There Gas in the Bottle?

Is There Gas in the Bottle?

Bernzomatic torches consist of two parts: the nozzle and a quart-size bottle of propane gas. If you're getting a weak flame, the first problem to suspect is that the bottle is nearly empty. There may be enough gas for a flame but not enough for a big, hot flame.

You can't actually check the gas level in the bottle because it doesn't have a gauge, and shaking the bottle to listen for the sloshing sound of liquid propane won't help either because you can't hear it. The best solution for this problem is to replace the bottle with a new one. Just unscrew the nozzle, screw it onto a new bottle, and give it a go. If the flame is still weak, there's a blockage in the nozzle.

Disassemble the Nozzle and Clean the Screen

Disassemble the Nozzle and Clean the Screen

Although it isn't obvious when you look at it, a Bernzomatic nozzle comes apart. Just grip the top of the nozzle with one hand and the base or bottle with the other and unscrew the top. When you get it apart, take a look through the upper part of the nozzle. There's often a little screen in there, and when the screen gets clogged with soot, you won't be able to see through the nozzle.

The best way to clean the screen is to blast compressed air into the nozzle. If you don't have a compressor, you can use an inexpensive can of compressed air. If that doesn't clear out the soot, try soaking the nozzle for an hour in a small bowl filled with a strong solvent, such as lacquer thinner, or spray it with carburetor cleaning fluid. Blow it out again after soaking and if you can see light through the nozzle, reassemble it and give the torch a go.

Clean the Gas Aperture

Clean the Gas Aperture

When you disassemble the nozzle, you'll notice that the lower part terminates in a dome shape, and right in the middle of the dome is a tiny hole that allows the gas to spray through. If this hole is clogged, there won't be enough gas for a strong flame, so you have to clean it.

Unscrew the base of the nozzle from the propane bottle and blast compressed air through the base while you hold your thumb over the aperture. That may be enough to clear it, and if so, you'll feel the air on your thumb. If not, you can try poking the aperture with a needle to clear debris, or you can soak the base of the nozzle in a solvent or spray it with carburetor cleaning fluid. Taken together, these procedures should clear the aperture, so when you reassemble the nozzle and screw it back on the propane bottle, you should have a strong flame.