Techniques For Soundproofing Floors

Two types of sound can pass through floors and make life difficult for people living downstairs. The first is impact noise, such as the sound of shoes walking on hardwood or furniture being dragged across the floor. The second is airborne noise, including the sound of a TV, sound system, loud talking and the odd operatic concerto from the shower. An effective floor sound control system has to address both types of sound.

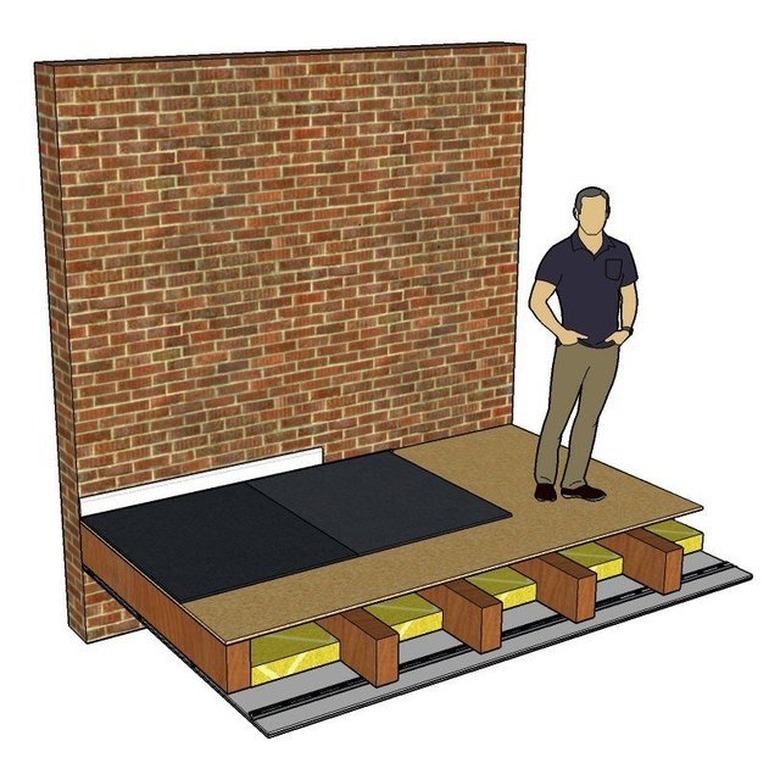

Just as it is for soundproofing walls, the best time to soundproof a floor is during initial construction, when the joists are exposed and the subfloor hasn't yet been fastened down. At this time, it is fairly easy to install materials that deaden impact vibrations and other materials that absorb airborne sound directly into the floor framing. The next best time is during the installation of a new floor covering, when you can install one or more layers of dual-purpose soundproofing material.

If you aren't planning to do any work on the floor, you can still provide some soundproofing by simply carpeting the floor. In fact, carpeting is de rigueur in some older multi-level dwellings, such as New England's famous brownstones. Many landlords include a lease clause that requires tenants to maintain carpeting on 85 percent of the floors in the unit. Carpeting creates surprisingly good soundproofing. It isn't as good as a dedicated soundproofing system installed during floor construction, but you can improve on it by installing a sound-absorbing barrier underneath it.

Types of Floor Soundproofing Materials

Types of Floor Soundproofing Materials

A wide variety of soundproofing materials is available, and the best choice depends on a number of factors, including:

- Stage of construction

- Desired level of soundproofing

- Type of noise

- Budget

Perfect soundproofing is an ideal, and you often have to settle for something less than perfect, especially if you're soundproofing a floor that has already been built. However, you can get closer to the ideal if you're in a position to incorporate more than one soundproofing material into the floor, including both materials that separate layers of wood to prevent impact vibrations from passing through, and absorbent materials that dampen airborne vibrations.

Joist Isolators

Joist Isolators

If you're still constructing the floor, consider installing joist isolators on top of the joists before you screw down the subfloor. Joist isolators separate the joists from the actual subfloor and prevent the transmission of impact sound. These isolators can also absorb a certain amount of airborne noise, but they are best used in conjunction with a filler material installed between the joists.

Tip

If the floor is already built, you can still incorporate joist isolators into a second layer of subfloor that sits on top of the original floor. When used this way, the isolators go on the bottoms of the joists forming the new floor.

Resilient Channel

Resilient Channel

Resilient channel is a type of flat, C-shaped metal stripping that decouples the ceiling or wall drywall from the joists or studs, providing an extra layer of vibration attenuation. They can be installed to reduce sound transmission either on ceilings or walls. Resilient channels are installed by attaching a flat flange at the base of the "C" to the joists. The drywall is then screwed to the flat top surfaces of the channels, which allows the entire drywall layer to float away from the joists.

Resilient channel was developed by United States Gypsum, the manufacturer of Sheetrock, and it's one of the original soundproofing options. By itself, resilient channel isn't hugely effective, but it's inexpensive. It works best when used in conjunction with other soundproofing methods.

Acoustic Filler

Acoustic Filler

Acoustic filler is a sheet material that usually is installed before the subfloor is completed, although also can be installed in a finished floor by removing the drywall from the ceiling below and installing the material up against the bottom of the subfloor. Acoustic filler looks like thermal insulation, and in fact, it is similar. If you prefer to install rock wool in the joist cavities as an alternative, you'll get approximately the same level of sound insulation. You can even use fiberglass batts as a sound-absorbing filler material, but it won't work quite as well. Unlike thermal insulation, acoustic filler comes in various soundproofing ratings, so you can choose the sound insulation level that is most appropriate.

Soundproofing Underlayment

Soundproofing Underlayment

If you're installing a new floor covering, you have the option of installing a soundproofing layer underneath it, before installation. This underlayment material comes in various thicknesses and densities, and it effectively deadens impact vibrations. You can install this material under hardwood and laminate floors and, if you purchase the right material, under tile floors as well. Tile floor underlayment sticks to the subfloor and is rated to accept a layer of standard thin-set mortar on the exposed surface.

Noise Dampening Adhesive

Noise Dampening Adhesive

Viscoelastic adhesives, of which Green Glue is the best-known example, uncouple layers of plywood or drywall to prevent the transmission of vibrations. The best way to use this material is to spread it on the existing subfloor and lay another sheet of subfloor material on top of it. The Green Glue creates a small gap between the layers, which reduces sound transmission. You can also spread it on the ceiling below the floor and cover it with an extra sheet of drywall.

Tip

The company that manufactures Green Glue also sells tape that you can install on the tops of the floor joists before fastening down the subfloor. This tape is an alternative to joist isolators. The company also manufactures soundproofing caulk for sealing the edges of the floor under the baseboards and around vents.

Soundproofing an Existing Floor

Soundproofing an Existing Floor

If your floor is still under construction, you can incorporate any of these soundproofing methods, but your options for an existing floor are more limited. You'll get the best results if it's possible to remove and replace the drywall from the ceiling below the floor. In that case, you can employ any or all of the following methods:

- Fill the cavities between joists with acoustic or thermal insulation.

- Install joist isolators or joist tape on the exposed joists.

- Screw resilient channel to the joists.

- Install a double layer of drywall separated by a generous application of noise- dampening adhesive.

If demolition is out of the question, you can still install an extra layer of drywall on the ceiling below, using adhesive. The extra bulk of the new drywall, together with the noise dampening provided by the adhesive, greatly reduces the transmission of impact vibrations.

If you're looking for a quick solution with a minimum of remodeling effort, spread thick carpeting on the floor. The pile of thick carpeting absorbs airborne noise while deadening the sounds of footsteps and other impacts. If you already have a favorite carpet but it isn't very thick, put a layer of sound-absorbing underpadding beneath it. You'll find a bewildering selection of underpadding products, including latex and foam, bonded polyurethane and waffle rubber. The best materials for soundproofing are synthetic fiber, jute and felt pads, because they are denser and thicker than other materials.

Tip

The ideal carpet padding thickness is 7/16 inches. Anything more than that creates installation problems and probably won't provide enough extra soundproofing to warrant dealing with those problems.