Everything To Know About Installing Terrazzo Countertops And Floors In Your Home

Terrazzo is in the midst of a major moment in home decor, both as a material for floors, countertops, furniture and objects, and as print inspiration for other materials, like fabric and wallpaper. Terrazzo has a long history, and while its popularity as a design trend has waxed and waned, its durability means its never really gone anywhere; the next time you're in the lobby of a corporate office building, at the dentist, or in a food court mall, keep your eye out for terrazzo's familiar flecks. If you're considering terrazzo for your home we'll clue you in on: what it is, how it's installed and used, the ways you can use it, how much it will cost, and companies that can help get your terrazzo dreams started.

What Is Terrazzo, Anyhow?

What Is Terrazzo, Anyhow?

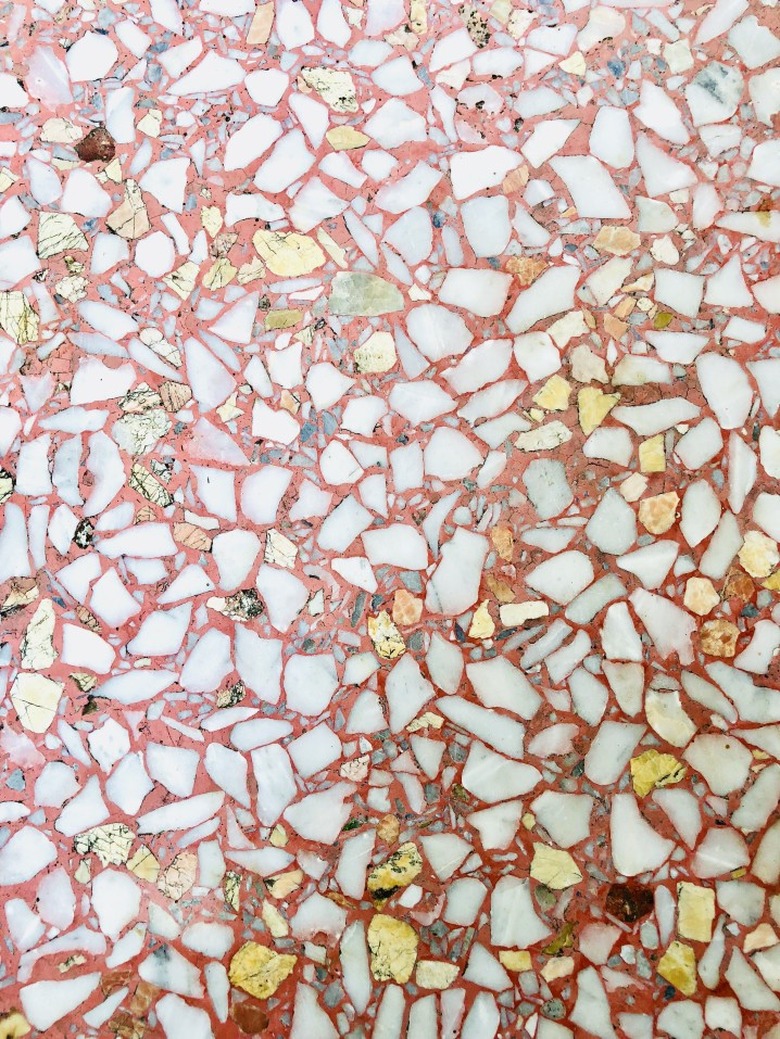

Terrazzo is a composite material made out of cement or epoxy-resin that's been mixed with chips of aggregates compounds like marble, stone, glass, mother of pearl, abalone shells, and many others. Terrazzo is most commonly used for flooring, and can be installed in two forms — traditionally and most commonly, it's poured in situ, a Latin phrase meaning "on site." Alternatively, it can be set into pre-made tiles or panels, which can also be used for countertops, walls, stairs, and other flat surfaces. Terrazzo can also be poured into custom molds to make sinks, bathtubs, furniture, and home decor items.

Epoxy-Resin vs. Cement

Epoxy-Resin vs. Cement

According to Michael Blackburn of Master Terrazzo Technologies, for many years, indoor terrazzo was primarily installed with a more traditional cement-based in situ system called sand-cushion terrazzo. All terrazzo flooring systems start with a cement substrate, but the sand-cushion system also has a bed of sand in between to create movement that mitigates the potential for cracking. However, sand-cushion terrazzo is dense and heavy — about three inches thick and approximately 30 pounds per square foot — and requires a lot of cement and aggregates.

Around 1963, the epoxy resin-based thinset terrazzo system was developed and completely changed the game, to the point where now, Blackburn says, "epoxy-based terrazzo makes up an approximate 95-plus-percent of the market share on a horizontal pouring surface." Thinset terrazzo is approximately 3/8-inch thick and three to five pounds per square foot, so it's thinner, lighter, and thus requires significantly less material. Resinous systems are also much less porous than cement, and more flexible, so they're less prone to cracking.

Color & Customization

Color & Customization

Color has been a big factor in the popularity of epoxy-resin-based terrazzo. Both cement and epoxy resin can be pigmented in just about any color imaginable, but if you have very specific color in mind, epoxy resin-based is a safer bet.

"Matching color with the resinous systems is just like matching paint in that it's a liquid medium with a liquid pigment," Blackburn says. "We can sit down with a client and 100 different types of chips — marble, glass, and mother of pearl — and a paint fan deck, and they can pick hot pink if they want to, or fire engine red, or more often than not, a really rich, saturated black or gray, or a pure white, as opposed to sort of the more approximate colors that you'll get from from cement."

The unlimited spectrum of color options reflects one aspect of terrazzo's potential for infinite customization. The aggregates — marble, quartz, many types of glass, mother of pearl seashells, and granite being the most common — can be combined and the size of the chips can also be customized.

"The big trend we're seeing now is large aggregate terrazzo, sometimes called Venetian terrazzo, where we have these large pieces of aggregates," Blackburn says. "We've also seen the resurgence of a terrazzo system called Palladiana. You'll see it walking around Venice in these very, very old installations, but also in diners, actually, throughout New Jersey and Pennsylvania, from back when they used to have some really impressive decor in diners. Palladiana is where we take stone tiles or pieces of stone, they're fractured, they're adhered to the concrete, and then standard terrazzo is troughed around them, so it almost looks like they're massive softball-sized pieces of aggregate."

If you're budget is equally as unlimited, terrazzo can be used as the medium for intricate designs, patterns, and logos.

Cost: Terrazzo Ain't Cheap

Cost: Terrazzo Ain't Cheap

Cement is technically cheaper than epoxy resin, but cement-based terrazzo is not necessarily more cost-effective. For starters, you need a lot more of it, and, because terrazzo is manufactured and installed on the job site, you also have to consider the labor costs, which include mobilizing all that heavy cement, in addition to the aggregate materials and a massive terrazzo grinder.

"Cement is really laborious and tough to work with," Blackburn says. "Where you tend to see cement-based terrazzo systems used more often is in areas where labor costs are particularly low. In other words, the cost of materials versus cost of labor is lower on labor and so they're able to work with the material a little bit more for less money and make up for some of that difference in cost. Whereas somewhere like Manhattan, where labor is quite expensive, there's going to be a pretty extreme difference between the amount of labor it takes to put in a cement system versus an epoxy system. Therefore, the epoxy-based systems are going to actually be as affordable if not more affordable than the cement-based systems."

Economy of scale is why terrazzo hasn't really boomed for residential projects — the cost of mobilization for the machinery doesn't diminish with the size of the job. In fact, to make a small project worth it to the terrazzo contractor, the cost may even go up. It's only with larger commercial projects that the cost of mobilization can be offset by the cost of materials and labor. Suffice it to say, if you want to install a terrazzo floor in your kitchen, expect to pay a pretty penny, and maybe consider paying a little extra to do the bathroom, too.

"Usually when somebody is willing to spend what it takes to do a residential terrazzo application, the difference in cost between cement and epoxy is not going to be that great," says Blackburn. "So they're going to go with the higher performing material which is going to be the thinset epoxy terrazzo."

Terrazzo Tile

Terrazzo Tile

There is one other option for smaller residential projects: terrazzo tile. Often less expensive than in situ terrazzo, the tiles are just as customizable, but they're typically installed with grouting in between so there isn't that same seamless look. Blackburn says that some manufacturers have come up with tile systems that are thinner than traditional terrazzo tile and utilize a "butt joint" rather than grouting in order to achieve the poured terrazzo look, but at a slightly cheaper price point.

However, "it's really not, I think in practice, quite what it is in theory," Blackburn says. "The tiles are so thin — 1/8" versus 3/8"-1/2" for traditional tile — that there's a lot of warping at that point, at least on occasions that I've seen. I recommend the traditional thickness terrazzo tile, and that will be less expensive than poured terrazzo, but it's going to also have grout joints to collect dirt. So it doesn't look like real terrazzo."

Next Steps

Next Steps

If you think terrazzo is right for you, the most important step is to find a terrazzo contractor, ideally in the near vicinity, since the further the materials and machinery have to travel, the more expensive the mobilization costs. The National Terrazzo & Mosaic Association has a list of licensed terrazzo contractors who are specifically trained in the terrazzo trade.

If traditional poured terrazzo is too expensive or otherwise not ideal for the project you have in mind and you want to try terrazzo tile instead, here are some options we recommend:

DZEK: Divined by designer Max Lamb, DZEK's Marmoreal terrazzo has large chips of colorful marble aggregates set in creamy white or jet black resin and is available in two sizes of tiles and large slabs, as well as pre-cast bathroom furniture (including a terrazzo toilet!) and other home decor pieces.

Terrazco: This company offers pre-cast epoxy resin-based terrazzo in tile form, as well as shower stalls, countertops, and wall bases.

Fritztile: Fritztile has been making terrazzo tile for over 50 years and in addition to their own wide range of colors and aggregate mixtures, they can create custom tiles in any color and chip size imaginable.

Terrazzio: This company sells just 12 colors of terrazzo tile, but in four larger-than-average sizes which are installed with their own grouting alternative called Metazzio.