What Is Roof Flashing?

Shingles and other types of roofing can cover any expanse of roof, no matter how large or steep. But when it comes to the joints or seams where the roof meets walls, chimneys, pipes or skylights, shingles need help. That's where flashing comes in. Flashing serves as a bridge between the shingles and the vertical (or non-roof) elements of a rooftop or between two different roof planes. Most flashing is made of thin, rust-resistant metal, like galvanized steel or aluminum, but it can also be rubber or other materials.

How Flashing Works

How Flashing Works

Like shingles, flashing works on the simple principle of overlap: It slips underneath an upper material and overlaps onto a lower material to create a bridge that allows water to flow from one plane to the next. Without flashing, these joints would have to be sealed with caulk alone, and caulk joints last only so long before they crack and leak. Flashing is much longer-lasting and far more reliable than any caulked joint (although flashing is often sealed with caulk for added protection). Roof flashing comes in many different types for specific applications.

Step Flashing

A piece of step flashing is a sheet-metal "L" or angle about 6 to 12 inches long. It is used most commonly to flash the joint where a roof plane meets the vertical surface of a wall, dormer or chimney. It is called step flashing because the pieces step up the roof, just like shingles do. In a typical installation, step flashing is layered into the shingles, one on top of the other, working from the bottom up. Step flashing is particularly convenient and inexpensive because it involves simple, standard parts that require no custom fabrication or special fitting.

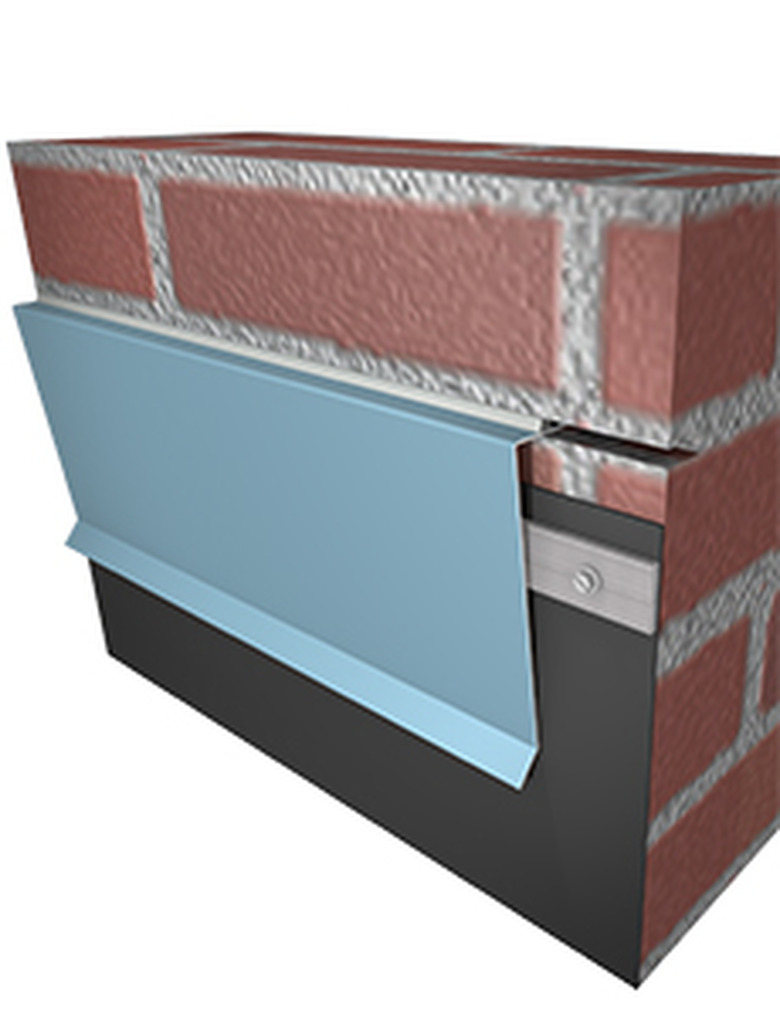

Counterflashing

With step flashing, the vertical half of the L slips up underneath the wall siding, while the horizontal half rests on top of the roof, creating the water-shedding overlap. However, when there's no siding to slip under, such as with a brick chimney, the roofer often must use counterflashing to cover the vertical half of the step flashing. Counterflashing can be applied to the surface of the vertical element—and rely on a caulk seal along its top edge—or it can be laid into a mortar joint during the chimney or wall construction or fitted into a slot (called a reglet) cut into the wall or chimney.

Pipe Flashing

Sometimes called jack flashing or boot flashing, pipe flashing typically includes a dome-shaped rubber boot with a hole that slips over a pipe penetrating the roof. The dome is attached to a flat metal base that is layered into shingles or sits on top of metal roofing.

Valley Flashing

The line where two sloping roof planes meet is called a valley. Valley flashing lies under the shingles on either side of the valley and creates a channel for water runoff, sort of like a river between two mountains. It is usually either a roll of flat metal or a pre-formed channel with a small peak at its center, giving it the nickname "W flashing."

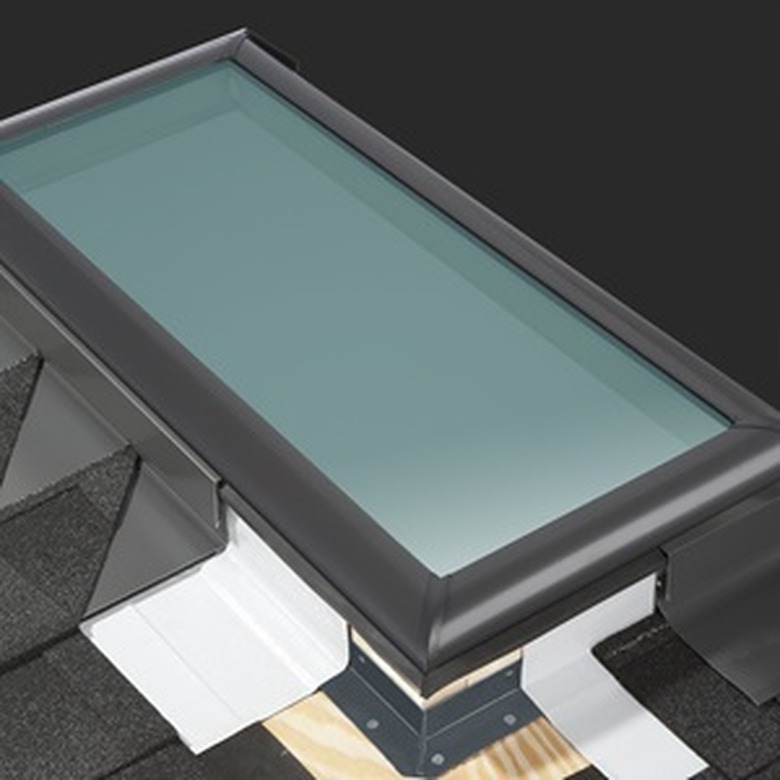

Skylight Flashing

Along with chimneys, skylights are some of the most challenging features to flash on a roof. In fact, when skylights leak, it's usually due to improper or failed flashing rather than because the skylight itself is leaking. Skylight flashing typically begins with a single piece of angle flashing along the top of the skylight curb; this is called the head flashing. The sides of the curb usually get standard step flashing, and the bottom gets another single piece called sill flashing. The head and sill flashing are either custom-cut and fitted during the installation or they are prefabricated to fit a specific curb size.

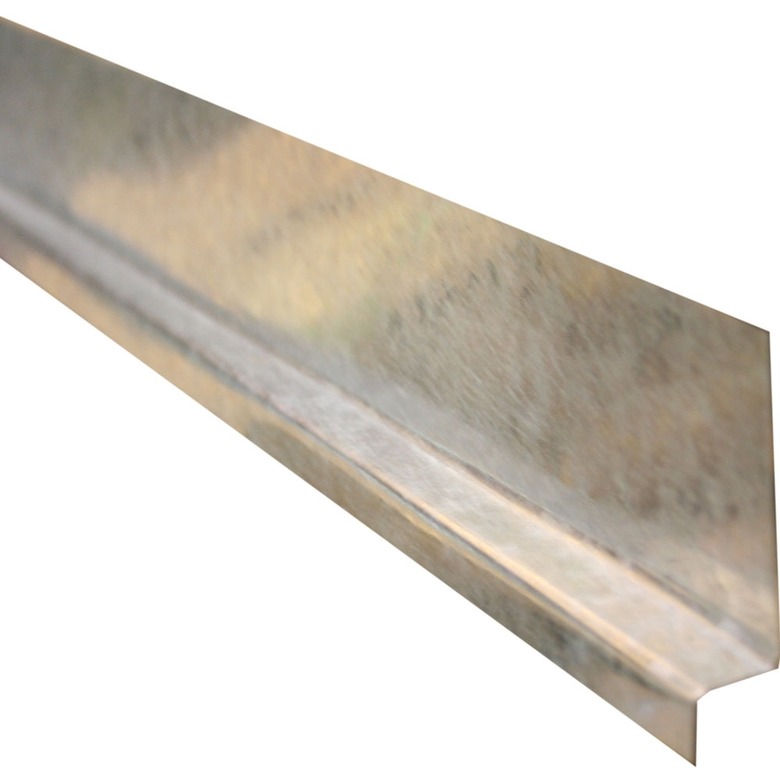

Drip Edge

Drip edge is a metal strip that is installed along the edges of a roof. It has a flat top (about 2 inches wide) and a perpendicular leg that has a little kick-out lip at the bottom. Drip edge supports the edges of the roof shingles (which overhang the roof a bit) and help send water into the gutter rather than onto the fascia board behind the gutter. When gutters are installed, their back edges are slipped under the kick-out lip of the drip edge.

Z-Flashing

Z-flashing is most commonly used to flash between wall siding and window or door trim but is also useful for some roof applications. It has a top vertical section that slips behind the siding, a horizontal section that covers the trim or other element and a bottom vertical section that laps over the trim. It gets its name from the Z-shape seen when the flashing is viewed from the side.

Flashing Tape

Flashing tape is 4- to 6-inch-wide butyl rubber tape with one sticky side. Its strong adhesive bonds to framing and other materials, and it can flex and stretch to seal corners and contours much more easily than sheet-metal flashing. Flashing tape has become standard for sealing window and door openings before the units are installed. On a roof, flashing tape may be used as a base layer under step flashing or skylight flashing. Unlike metal flashing, flashing tape is not designed to be exposed to the weather.