What Is Stucco?

Stucco is a durable and relatively low maintenance wall covering that has been popular in one form or another for millennia. The earliest forms of stucco were composed of lime, sand and water. To this mixture, plant or animal fibers (such as horsehair) were sometimes added for strength, waxes and oils to improve water repellency, and other materials to modify the stucco's workability. This lime-based formula was basically the same whether the covering was applied to exterior or interior walls, and in many European countries, both interior and exterior applications are referred to as "stucco." Stucco was also used for decorative features such as ornately carved vaulted ceilings, but here, of course, we are talking about lime plaster and not the later cementitious stucco.

Cement-Based Stucco

Cement-Based Stucco

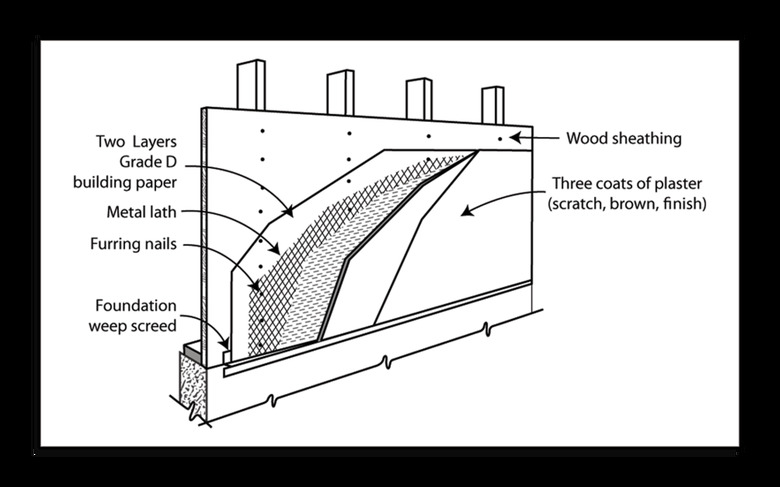

In England in 1824, Portland cement was invented and it quickly found its way into the exterior stucco formula. The addition of Portland cement to the lime, sand and water mixture yields a much harder but more brittle product than traditional lime stuccos. Unless your home is extremely historic, it's safe to assume that any stucco exterior in America will be Portland cement-based stucco (unless it's synthetic stucco; we'll talk about that later). There are two different systems of stucco application—the three-coat system and the newer one-coat system. In both systems, the wood exterior sheathing is first covered with waterproof building paper or house wrap, then metal lath is attached to the exterior sheathing and a stucco base coat is embedded in the lath. In the three-coat system, the base coat, known as the scratch coat, is crosshatched or furrowed to create keys for the subsequent coat. The second layer, known as the brown coat is about the same thickness as the scratch coat and levels out any irregularities in preparation for the finish coat. This finish coat carries the colorant, which is blended into the stucco mixture, and is also where any textural effects are added.

One-Coat Stucco

One-Coat Stucco

One-coat stucco systems add strengthening agents such as glass fibers and other proprietary ingredients to the base coat of the stucco. Some one-coat systems include a layer of foam board beneath the base coat for enhanced insulation properties. The finish coat, in both the one-coat and three-coat systems, can be either standard stucco mix or an acrylic mixture that is more water resistant and resilient than traditional stucco.

Moisture Control

Moisture Control

As with any cement-based material, stucco is naturally porous and can allow moisture to infiltrate the siding. That's to be expected and is not a problem as long as that moisture is stopped at the moisture barrier and either channeled away by means of weep screeds at the foundation or allowed to dissipate through the permeability of the cement. This ability of the stucco to "breathe" and thus release moisture that accumulates is essential to its long-term integrity and that of the structure beneath. For that reason, among others, painting stucco is a bad idea.

When moisture does get trapped beneath a stucco surface, the structure can degrade. The metal lath begins to rust, and when it rusts it expands, cracking the cement. The nails attaching the lath can rust through, releasing the lath from the wood sheathing. If the moisture penetrates the vapor barrier, the result can be mold and rot in the house structure itself. In situations where a section of stucco has separated from the wall and broken off—usually at the foundation level—it is necessary to cut back the damaged stucco until you reach solid material. Inspect the wood sheathing for damage and replace, if necessary. The repair will require new metal lath and multiple coats of stucco mixture, as in the original wall covering. Convincingly matching the original texture of the finish coat will likely entail practiced skill. This may be a repair best left to a professional.

Synthetic Stucco

Synthetic Stucco

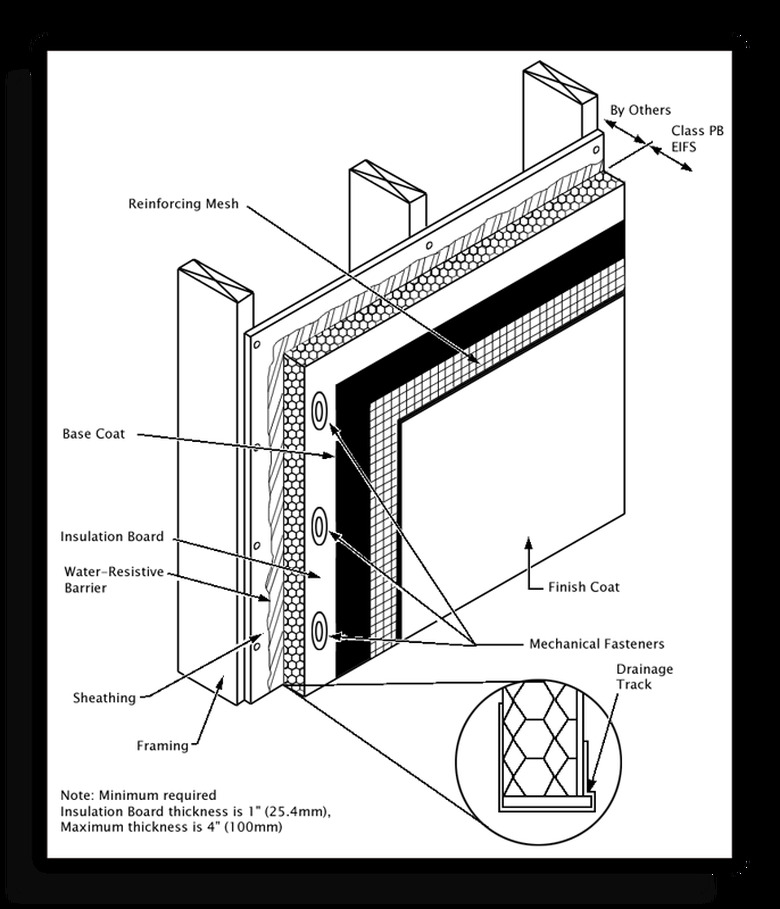

Synthetic stucco was first introduced in America in the 1970s under the brand name of Dryvit and became popular in home construction. Also known as EIFS, which stands for Exterior Insulation and Finish Systems, synthetic stucco is a ready-to-install panel that combines an insulation board or cement board core with an outer finish that resembles stucco. The insulation layer, when present, gives EIFS an advantage over traditional stucco in energy efficiency. Synthetic stucco is also more economical to install than traditional stucco, but EIFS has had a checkered history. Originally introduced in Europe, where buildings were predominantly stone or masonry, EIFS worked well and with few problems. When the system that had been successful in Europe was imported to the United States, its popularity took off and it was widely used both in commercial and in residential structures. But by the late 1980s, an alarming number of EIFS-clad homes were showing serious water damage—not only to the cladding but also to the structure of the house itself.

References

The Lesson of EIFS

The problem with the European-style EIFS is that it's water resistant on its face and it doesn't breathe. Moisture that penetrates the cladding will be held there, unable to dissipate, ultimately making its way to the moisture-vulnerable wood, drywall and insulation beneath. As many in the construction industry will tell you, water always wins. Moisture will find a way through any barrier and if you don't channel it away, you suffer the consequences. On stone and brick buildings, water infiltration was less of a problem, but when applied to wood frame structures, it resulted in costly damage and numerous lawsuits. As a result of the problems encountered with early versions of synthetic stucco, drained EIFS systems have been developed for use on wood frame homes. Drained EIFS systems build in drainage channels and advanced moisture control while still providing the economy and energy efficiency that made the earlier versions of the product so attractive.