How Does A Hot Water Recirculating Pump Work?

If your water heater is in the basement or on the other side of the house from the kitchen or bathroom, you may have to wait for quite a while for hot water when you turn on the tap. This is more than just an inconvenience, it's a waste of potentially thousands of gallons of water per year, and water is an increasingly precious resource. A recirculating pump can solve this dilemma.

The function of a recirculating pump is to keep hot water moving through the pipes so that it's available at the faucet immediately. It uses about the same amount of energy as a bathroom exhaust fan, and some systems are so efficient that the energy expenditure is even less than that.

If you choose to install a recirculating pump, you'll have some up-front costs, but you can keep these low by choosing a system that employs your existing pipes. A more extravagant system requires installation of an extra hot water pipe to provide a return path for unused hot water, but you can also choose a system that uses the cold water pipes for the return path. In this type of system, the only expenses are the pump. a few extra pipe fittings and the labor to install them.

The Pump Is the Heart of a Recirculation System

The Pump Is the Heart of a Recirculation System

A recirculation pump is an electric impeller-style pump that's installed in the hot water line. It has 3/4-inch pipe thread connectors, and you place it in the hot water line next to the water heater or near the fixture that needs the hot water. The pump runs on 120 VAC power and plugs into a standard outlet.

Other important components of a recirculation system include:

- A check valve, which ensures the water flows in only one direction. This is a requirement for any water circulation system.

- A temperature sensor, or aquastat, to monitor the water temperature and shut off the pump when it's high enough. This is an energy-saving feature that not all systems have.

- A timer to allow you to program the pump to come on when at times of the day when you usually need it. This is another optional energy-saving feature.

Higher-end pumps come with these features pre-installed. If you have a basic pump, you have to install the other components separately.

Depending on the type of system you install, you may need to install a double tee bypass valve fitting on the fixture that uses the hot water. This fitting has connections for the hot and cold water supply hoses, and it provides a path for the hot water to enter the cold line so that it can return to the water heater via the drain fitting on the tank.

Types of Hot Water Recirculation Systems

Types of Hot Water Recirculation Systems

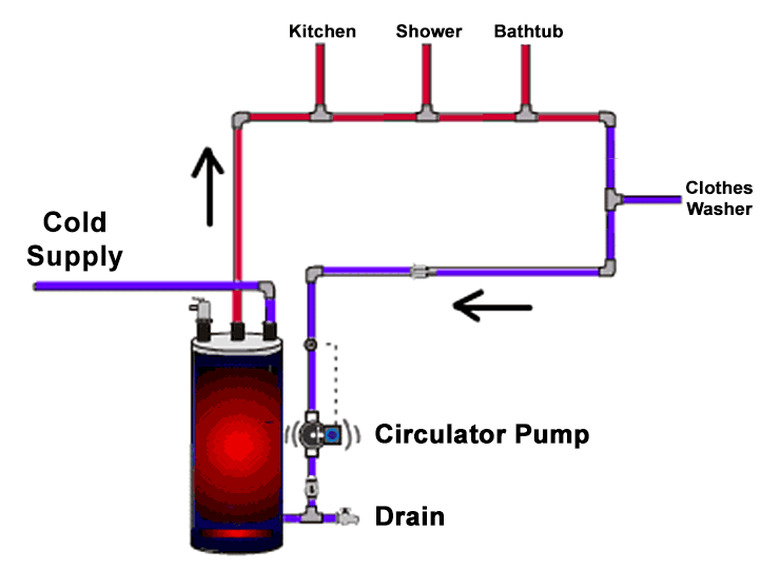

The best time to install a recirculation system is when you're installing new plumbing, because that way, you can install a separate hot water return pipe that connects to the water heater. This extra pipe, together with the hot water pipe, creates a dedicated loop that can feed each hot water fixture. The pump is installed near the water heater, and all it has to do is circulate water through the loop.

Tip

If the water heater is situated underneath the fixtures calling for water, you don't really even need a pump. Once you've constructed the loop, you can rely on gravity, or more accurately, on the fact that warm water rises and cold water sinks, to circulate the water. Such a gravity-fed system, is probably the least expensive way to ensure you always have hot water at your faucets.

When installing a recirculating system in existing plumbing, it usually isn't feasible to install a third water pipe. The alternative is form an integrated loop system using the cold water pipes. The hot and cold water pipes at every fixture that needs hot water are joined by a double-tee bypass valve that links the hot and cold water pipes. A pump, usually installed near the fixture farthest away from the water heater, monitors temperature and switches on when the hot water temperature falls below a preset value. The pump causes a constant slow stream of water to flow from the water heater to the bypass valve and back again, which keeps the water in the pipes comfortably warm. When you turn on a faucet tap, the bypass valve closes, allowing water to flow normally through the pipes. But because the water in the hot water line is already warm, you don't have to wait for gallons of cold water to empty out as the hot water travels to the faucet.

Note: If there is not access to a power outlet under the sink, the pump can also be installed on the hot water outlet pipe running from the water heater.

One of the problems with integrated loop systems is that, by forcing hot water into the cold pipes, you end up creating a mirror image of the original problem: You have to let the cold water run for a while before it actually gets cold, which wastes water. To counter this problem, double-tee bypass valves—also known as Comfort valves—often come with temperature sensors, and they close when the temperature rises above a preset value, such as 102 degrees Fahrenheit. This prevents really hot water from circulating through the cold pipes.

Making Recirculation Systems Energy Efficient

Making Recirculation Systems Energy Efficient

If you just left the pump on to continuously recirculate water, the energy expenditure would cancel out the benefit of the saved water, and then some. For efficiency's sake, there must be some means of activating the system only when hot water is needed.

Some systems are manually activated; there is a button located on the sink cabinet that you press before turning on the faucet. Most systems, however, are automatic. A sensor in the pump or installed somewhere in the hot water line monitors temperature and switches on the pump when the temperature falls below a certain value. Some other systems use a timer that the homeowner can program to turn on the system at particular times of the day.

Either way, a significant amount of heat loss occurs when the system isn't running. To minimize this, it's important to insulate the pipes with foam pipe insulation, fiberglass or some other material.