Annual Furnace Maintenance: What You Can Do And What's Best To Leave For The Pros

If you're lax about furnace maintenance, you might not notice the effects until you begin to notice a rise in your energy bills. While that's a nuisance on its own, it's also a warning of more serious problems to come if you don't start giving your gas furnace the TLC it needs.

A rise in energy costs is a sign that the furnace is working harder than it should, which is usually because dirty filters are hindering the airflow, and it probably won't be long before something gives. Poor airflow can overheat the combustion chamber, causing cracks that can release toxic gases, like carbon monoxide, sulfur dioxide and nitrogen dioxide, and perhaps causing the furnace to lock out, or shut down completely. In fact, failure to maintain your furnace can even void the warranty.

Keeping the filters clean and maintaining good airflow are important, but they aren't the sum of furnace maintenance by any means. A typical gas furnace is full of moving parts, sensors and other equipment that needs to be regularly tested, lubricated and cleaned. Homeowners can do a lot of this maintenance themselves, but some procedures are best done by an HVAC technician during a yearly furnace tune-up and inspection. Licensed pros are a bit like doctors: They have specialized equipment for monitoring air quality and temperature changes that allows them to diagnose developing issues that could become serious if left unaddressed.

Get to Know Your HVAC System

Get to Know Your HVAC System

Because most of a home's ductwork is in the basement or crawl space or hidden behind walls, most people don't pay much attention to it. Like an octopus, it has tentacles that reach every room in the house, emanating from a body that looks like little more than an unimpressive steel box. Except for the vents that pump out conditioned air or return room air for recirculation, the ductwork system is completely sealed — or at least it should be. To keep your energy bill as low as possible and to prevent overheating, which can shut down the furnace, it's important to check the duct system periodically for leaks and to keep them clear of debris that can hinder airflow.

The steel box in the basement or attic — the body of the octopus — contains a burner, a heat exchanger to keep the burner safely sealed and to distribute the heat it produces and a blower to circulate the heated air. If the system is also used for cooling, you'll find evaporator coils in the box connected by a length of tubing to a compressor outside. Both the heat exchanger and evaporator coils are positioned in the plenum, which is the large area above the burner where the ductwork is attached. Most systems have dampers in the plenum and elsewhere in the ductwork that allow you to control the airflow and regulate temperature in different parts of the house.

The blower, which HVAC pros sometimes call the squirrel cage, is a finned metal wheel that spins on a horizontal axis and is driven by a motor. It is located at the bottom of the box. Along with the gas igniter and gas valve, it is connected to a control panel wired to a household electrical circuit. The panel receives signals to turn on the gas, ignite it and start the blower from a thermostat located somewhere in the house, usually on a wall in the middle of the building. Maintaining the electrical and gas systems is best left to a pro, but there are quite a few things homeowners can and should do themselves to keep everything running smoothly.

Annual Furnace Maintenance for Homeowners

Annual Furnace Maintenance for Homeowners

Most homeowners are nervous about working inside the furnace, and that's prudent, but there's little danger as long as you remember to turn off the power and shut off the gas before removing the furnace cover. Most covers have plastic knobs that you can turn by hand, and when you turn them all 90 degrees counterclockwise, the cover releases so that you can lift it off. Some older furnaces have screws that require a Phillips screwdriver or a socket wrench. Once you've exposed the guts of the furnace, the list of maintenance tasks you should complete once a year depends on your facility working with machinery, but anyone can complete the most essential ones:

- Check the burner: Remove the burner cover, which is a rectangular metal plate covering the burner assembly; it may simply lift off, or it may be attached by screws. Turn up the thermostat to make the furnace switch on. If the furnace has electronic ignition (spark ignitor or hot-surface ignitor), verify that it's working properly and then look at the flames, which should be steady and burning with a blue color. If the flames sputter or are yellow, the burners may need adjustment, which is a job for a pro, but you may be able to improve things by turning off the furnace, waiting for it to cool down and brushing carbon deposits off the burner with a small, stiff brush.

- Clean the pilot: If your furnace has a standing pilot, make sure the pilot flame burns with a steady bluish light. If it's sputtering or yellowish, turn off the gas and blow blockages from the pilot opening using a can of compressed air. If your furnace has an electronic ignition, it's still a good idea to blow dust from the pilot opening with compressed air.

- Clean the flame sensor: This is an easy task if you can identify the flame sensor and you know how to use a screwdriver. Turn off the power and the gas supply to the furnace. Unhook the wire from the flame sensor and remove the screws holding the sensor to the side of the burner assembly. Rub the sensor's metal probe with fine steel wool to remove carbon deposits and when it's shiny again, reinstall the sensor and reconnect the wire.

- Clean and lubricate the blower: With the furnace power and gas turned off, remove the screws holding the blower assembly to the burner chassis, lift out the assembly and turn it around so you can access the blower wheel. Brush dust off the fins with a stiff brush. If the blower motor has a drive belt, look for cracks and check the tension; you shouldn't be able to deflect it by more than 3/4 inch. If the belt doesn't have enough tension, loosen the motor bolts with a socket wrench and slide the motor to tighten the belt. The blower motor on old furnaces may have one or more oil ports for lubricating the motor. In this case, you can remove each oil port cap and add oil until it begins spilling out of the port and then replace the cap.

- Dust the heat exchanger: Dirt on the heat exchanger can cause overheating, so brush it off with a duster or blow it off with compressed air. If you have a heating system that doubles as a cooling system, clean the air conditioning coils with the duster or compressed air.

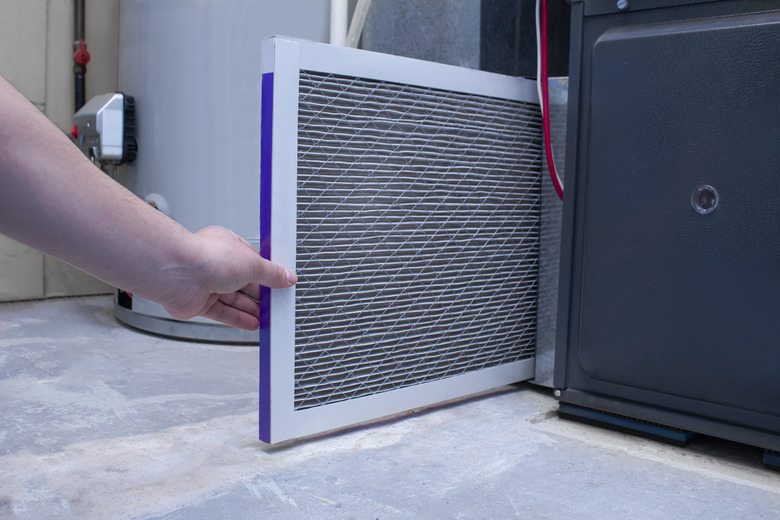

- Replace the air filter: The furnace filter needs to be replaced at least once a year but preferably every three months during the heating and cooling seasons. This is also a good time to replace the filter in the return air vent and any filters you have placed inside the vent registers.

- Inspect the flue and ductwork: Look for holes or corrosion. You can patch holes with aluminum foil tape (don't use regular duct tape), but if you find extensive corrosion, part of the flue will have to be replaced. Some of the ductwork will be inside walls or otherwise out of your reach. If you suspect leaks, an HVAC pro can verify that with a pressure test.

Annual Furnace Maintenance for Pros

Annual Furnace Maintenance for Pros

Even if you do yearly furnace maintenance yourself, you should still book a yearly tune-up with a service pro, who will conduct electrical and pressure tests to confirm that everything is working as it should. The technician's job will be a lot easier if you have completed your maintenance routine first, and that will probably save you money. If you didn't get around to your part of the job, the technician will take care of it as well as doing the following:

- Listen for strange noises: Before beginning a tune-up, most HVAC pros will turn on the furnace and listen for noises, such as humming or rattling, that point to the possible need for repairs. The noises could indicate a worn blower motor, a faulty transformer or loose components in the system.

- Test and adjust the burner and ignition system: If the furnace has a standing pilot, it has a thermocouple, and the technician will check its alignment and test the voltage and gas pressure. The same tests are necessary for the flame sensor in a furnace with an electronic igniter. The technician will also test the igniter and adjust it if necessary.

- Inspect and test the control panel: The technician will check for loose or miswired connections and verify that everything is working properly or replace any parts that have worn out. This inspection includes a test of the furnace's response to signals from the thermostat. If the house is frequently too hot or too cold or if the temperature fluctuates, the thermostat may need to be recalibrated, and this is a good time for that to happen.

- Adjust and deep clean the burner assembly: The service pro will disassemble the burner assembly and do a deep clean with a high-powered vacuum. This deep clean gives the tech a chance to correct any problems resulting from poorly adjusted burners, and besides making the furnace work more efficiently, it lengthens the life span of the equipment.

- Test the fan/limit switch: The fan/limit switch, sometimes called the roll-out switch, tells the blower fan when to switch on and switch off, and, when the heat exchanger overheats it shuts off the gas. The technician will conduct a voltage or continuity test to make sure it's working properly and replace it if necessary. Don't worry if it needs to be replaced; it's an inexpensive part.

- Inspect and lubricate moving parts: After disassembling the blower, the technician will check the belts and lubricate the motor as well as the blower axle as applicable. If the furnace includes an air conditioner, the technician will also inspect and lubricate (as needed) the condenser motor in the outdoor unit. This checkup also includes voltage tests of the condenser and blower motors.

- Look for cracks and leaks: You may have done this already, but because cracks and leaks can be dangerous, especially if they occur on the heat exchanger or the flue, the technician will conduct a detailed inspection. The tech will patch them or recommend a suitable course of action for ones that can't be patched, such as cracks on the heat exchanger.

- Clean the ducts: A full-on ductwork cleaning usually isn't necessary, and the EPA has found no evidence that it makes the air in the house any healthier, but debris collecting around the filters and vent openings impedes airflow and makes the furnace work harder, so as part of a furnace tune-up, an HVAC pro will check the vents and ducts and clear out any debris that is obstructing air. This is something homeowners can do, but a service pro is usually equipped with a more powerful vacuum with a longer hose that makes cleaning more effective.