Understanding The Parts Of Your High-Efficiency Furnace

We may receive a commission on purchases made from links.

High-efficiency furnaces are those with an annual fuel utilization efficiency (AFUE) rating of 90 or higher. In layman's terms this means they convert 90 percent or more of the fuel energy into usable heat. Standard furnaces, by contrast, typically have an AFUE rating around 80, so they are often known as 80 percent furnaces. Older furnaces were much less efficient than even today's standard models, with AFUE ratings in the 60s, but in 1975, the Department of Energy established a minimum efficiency rating of 78 for all new furnaces, and in 2015, they raised it to 80.

What sets high-efficiency furnaces apart from standard ones is a secondary heat exchanger in which exhaust gases from the primary heat exchanger are cooled and condensed into a liquid, a process that releases heat and makes it available for circulation. For this process to be effective, the high-efficiency furnace, which is also known as a condensing furnace, has to be sealed, so it needs a vent to supply combustion air from outside. A condensing furnace also needs a drain to get rid of the condensate, which is something you won't find on an 80 percent furnace.

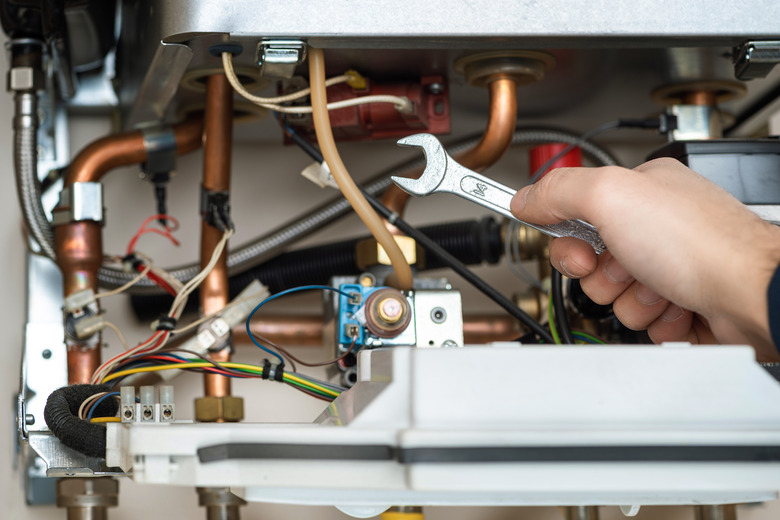

Apart from these differences, most of the other parts you'll find on a high-efficiency furnace are similar to those on a standard gas furnace. It's good to know about these parts and what they do so you won't be overwhelmed when you open the furnace access panel in an effort to diagnose a problem. If you keep your cool, you can even fix some of these problems yourself.

The Vents and Condensate Drain

The Vents and Condensate Drain

An energy-efficient furnace actually needs two vents. The burner flame needs oxygen for combustion, so one vent draws in combustion air while the other vent allows exhaust gases to disperse. The exhaust vent takes the place of the flue on a standard furnace, which is metal and extends through the roof. Because most of the heat has been removed from the furnace exhaust, the vents can be made of PVC instead of metal, which the corrosive gases would degrade, and the two vents are often incorporated into a single concentric pipe. Whether the furnace has one vent pipe or two, they typically run horizontally and extend a foot or so outside the house through the furnace room wall.

Homeowners are advised to check these vents periodically for blockages. Depending on how the furnace was installed, they may also find a 3/4-inch drain pipe nearby. This pipe can also be routed directly to a house drain, but when it extends outside, it should also be checked periodically for blockages, especially if you've noticed water on the floor around the furnace.

The Primary and Secondary Heat Exchangers

The Primary and Secondary Heat Exchangers

In a standard gas furnace, combustion — the burning of the fuel — occurs inside a series of open-ended metal tubes called a heat exchanger. The flames enter from one end, exhaust gases emerge from the other and are directed to an exhaust flue that extends through the roof and the heated air surrounding the metal tubes is circulated through the ductwork by the furnace blower. In high-efficiency furnaces, the exhaust gases enter a second, smaller series of tubes in which they circulate until they are cool enough to liquefy, or condense. The gases give off more heat as they condense, and this heat is conducted through the metal sides of the tubes and is added to the air being circulated by the blower.

The heat exchanger's main function is to contain combustion gases, which include poisonous carbon dioxide, and prevent them from being circulated throughout the house. A cracked heat exchanger is a serious matter, and it usually has to be replaced.

The Gas Valve, Ignition System and Burners

The Gas Valve, Ignition System and Burners

The gas valve is the interface between the gas supply, which can be propane or natural gas, and the burners. It's basically an electromagnetic gate valve that opens and closes according to signals from the thermostat. When the thermostat calls for heat and the gas valve opens, an ignitor is needed to light the gas. Many older furnaces have a standing pilot, which is a small flame that burns continuously and works like a lit match to start the flame. Because a pilot light must always be on, it wastes gas, so you won't find one on a high-efficiency furnace.

Instead, the most common ignition system is a hot surface ignitor, which is a resistive heating element positioned at the gas valve outlet. When the thermostat calls for heat, the ignitor heats up long enough to glow red hot before the gas valve opens.

When the valve opens and emits pressurized gas, the gas passes through a pipe and emerges at each burner orifice. The burners are metal tubes that typically need to be cleaned during a furnace tune-up, and each has a pair of fins that extend to the adjacent burners to ensure that the flame ignited by the ignitor spreads laterally to all the burners. This is important, because if any of the burners fails to ignite, it will discharge unburned gas into the furnace room.

The Blower and Blower Motor

The Blower and Blower Motor

The blower is a ribbed drum stationed at the bottom of the furnace that circulates the air through the furnace plenum, which is the cavity at the top of the furnace, and into the ductwork that is attached to the plenum. It comes on after the burners ignite to avoid circulating cold air and stays on for a while after the burners go off to circulate all the remaining warm air. The blower motor is direct-drive, so it doesn't need belts, and it's typically a variable speed ECM (electronically commutated motor) — another feature that increases energy efficiency.

Flame Sensor and Limit Switch

Flame Sensor and Limit Switch

Energy-efficient furnaces don't have a pilot, so they don't need a thermocouple, which is the sensor that detects the heat of the burning gas from a pilot light and sends a signal to keep the gas valve open. They still need a safety device to switch off the gas in case the burners don't ignite, however, and the flame sensor does this job. It's a small probe attached to a plate just above the burner farthest from the gas valve. It works like a thermocouple, sending a signal to the gas valve to stay open as long as there is a flame. If there is no flame, the flame sensor sends no signal, and the valve closes.

Another important safety feature is the limit switch, which has two functions. The first is to switch the blower on after the burners ignite and keep it on until the air in the plenum cools. The second function is to shut down the furnace if it detects overheating in the heat exchanger, which is usually the result of poor airflow caused by blocked venting or a dirty air filter. If the furnace overheats repeatedly, the limit switch will malfunction and throw it into lockdown mode, and it typically has to be serviced before it will run again.

The Draft Inducer and Pressure Switch

The Draft Inducer and Pressure Switch

Once combustion starts, it's essential for all the exhaust gases to exit through the vent, so high-efficiency furnaces have a small fan called a draft inducer positioned near the vent opening to create a draft that will suck out the gases. Located near the draft inducer is another safety switch called the pressure switch. Its job is to monitor the relative pressure inside the furnace and in the vent, and in the event of a negative pressure situation that could allow combustion gases to reenter the furnace, it shuts down the furnace.