Woodworkers: Stop Limiting Your Potential & Embrace The Glories Of CNC Routers

We may receive a commission on purchases made from links.

As a professional woodworker, I am both frustrated and confused by the vast number of woodworkers who refuse to accept CNC routers into their workshop. To some, the CNC narrative takes on the nature of John Henry: The battle of man against machine, of technology replacing our labor and skills. For them, perhaps, the idea of using a computer in their sacred woodshop feels invasive. But we're not here to debate why it's uncomfortable for many woodworkers: What I take issue with is that, regardless of intention, so many of them outright dismiss these workshops marvels.

This seems awfully shortsighted. Considering the transition from handheld hand-powered woodworking tools to those powered by electricity is long and well-documented, you'd think we would know better than to reject new technology. How are CNCs different?

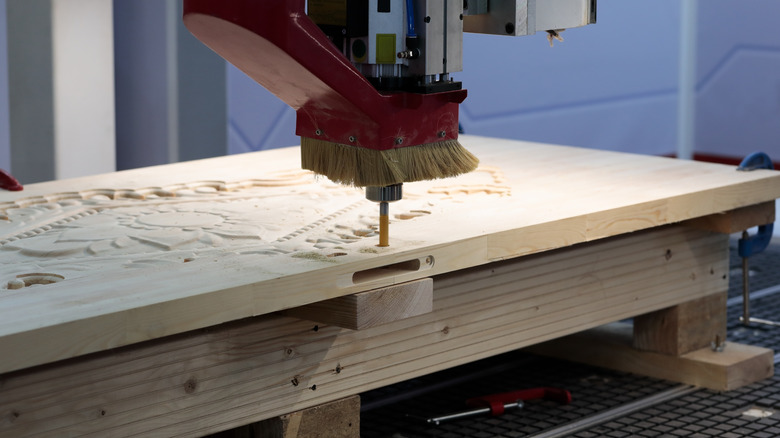

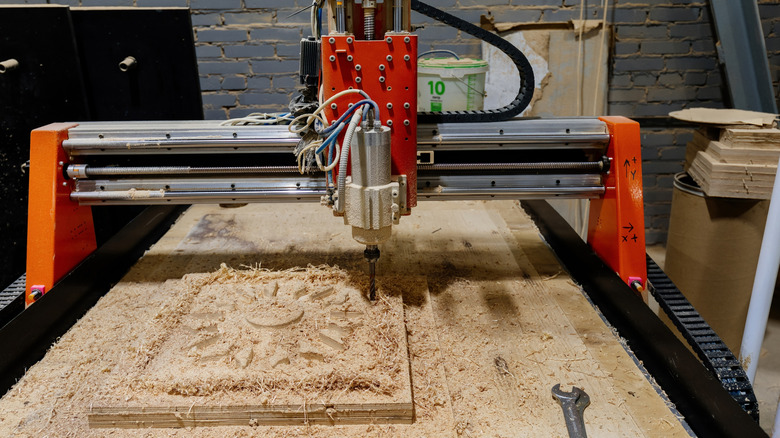

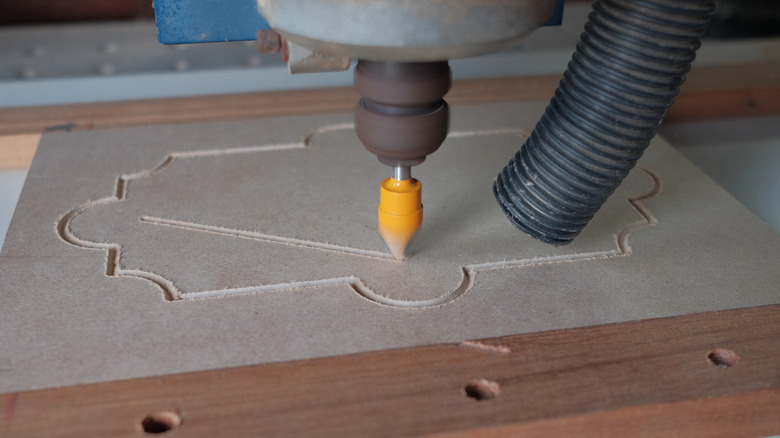

For those not familiar, small shop CNC routers mount the handheld routers that nearly every woodworker has in their shop on a gantry. This controls the movement of that router in three directions: Up and down is called the Z axis, side to side and front to back are the X and Y axes. The router spins a cutting bit at up to 25,000 rpm. CNC stands for computer numerically controlled and those numbers, the zeros and ones, are the programming needed to direct the cutter. When a program is successful you can repeat the woodworking process in a stunningly precise manner — exactly the same every time. And that's what makes them so great. Because CNC routers aren't a cheat code: They're just a dynamic new tool that we should embrace.

CNC routers are a fiery topic in woodworking circles, and here's why

Let's take a deeper look into the conflict between CNC router haters and fans like myself. What is the reason for such tension? Is the CNC router disdain simply the resistance of orthodoxy to change? The fear of the new and novel?

Whenever you see this topic brought up online, it's a minefield. On Reddit, debates can get very pretty technical. While certain woodworkers, like Redditor Beardmaster76, will argue with opinions remarkably similar to my own — in their words, "If someone says it's cheating tell them they better be using strictly homemade tools [made] out of stone" — others take issue with this stance. For example, in that same thread, Redwood_rambler came along and offered a more confusing comment. "I wouldn't say it's cheating, but I don't necessarily think of it as woodworking either." Whereupon jwd_woodworking seemed to hit on the heart of the matter, stating, "CNC substitutes skill with the programming for skill with the actual woodworking tools. The skills are very different in nature – hence the tendency for a lot of traditional woodworkers to view CNC as cheating."

I'm no stranger to being set in my ways. I have a healthy cynicism to claims that seem too good to be true. However, I won't ban myself from a tool that accomplishes great tasks with excellent precision out of orthodoxy, or some false sense that because of "programming" a woodworking tool doesn't count as woodworking. I don't think others should take this narrow stance, either. Deep down, I think it really comes down to resistance to change.

The heart of the woodworking argument against CNC routers

I'm going to take the long view here to put the question of "why hate CNC routers?" into perspective.

My father was a woodworker, much like me. The woodworking technology in my dad's shop was less sophisticated than you'll find in most small professional woodshops today. If you were to ask me back then what my job was, I would reply "woodworker." Today, in nearly every small pro-shop that sells handmade guitars, CNCs play an intricate part in their business. I am confident if you asked the people working in these shops if they were woodworkers, they would say yes. Who are you to say they are not?

The elephant in the room is the computer. The idea that learning to program a computer is not woodworking — it is, in the opinion of users like the Redditors mentioned above, something else. Now, the fact is that my CNC uses a software program that lets me use a graphical interface to just draw lines and circles on a page, and then it turns those lines into directions that my CNC can understand. No argument there. But is that really... well, programming? I guess that is technically true, but I am an old dog, and I learned that trick pretty fast, and I did not need to learn some sort of programming language. And am I "programming" my table saw when I set it to a specific width of cut? In another era, a table saw would've also been considered "cheating." It's all different technology to accomplish old tasks in new ways. And someone using a CNC router today is as much a woodworker as somebody using my dad's old technology was.

As a woodworker, here's why I use a CNC router

I have been woodworking for over 40 years, and I do all sorts of woodworking. Like every woodworker I know, I use templates to precisely shaped curved pieces. Table legs, guitar bodies, shaped headboards, table aprons with matching curved shapes ... anywhere we need non-rectilinear shaped parts to be accurate and identical. We use the templates to guide a handheld router with a pattern cutting bit. The problem comes if we make the template improperly, then each piece we make from it will be wrong.

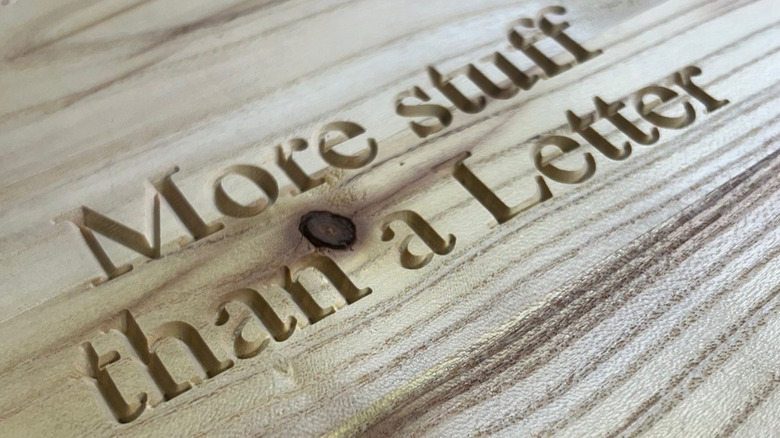

Guess what makes perfect templates? My CNC. Then, because it is faster than using the CNC to cut each piece, I use my handheld router with the template to form the actual pieces. I also use the CNC on projects that require lots of accurately drilled holes. I like to make cribbage boards, for example, but drilling 121 holes perfectly is hard for me. Not the CNC. While some folks use CNCs to form joinery like dovetails and mortise and tenons, that's not something I use it for often. I do like to make signs and plaques, though, the CNC is terrific for that. And while I can do inlay work by hand, it's also just more practical to use a CNC that will do the inlay work faster and more accurately.

Here is a practical example. I have three pairs of grandchildren, and so I used my CNC to make three sets of dominoes as Christmas presents. I've the skill and the tools to make them by hand, but the CNC made my life easier, and the grandkids were just as happy as they would've been if I hadn't used it.

Think of CNC routers as an addition to your woodworking toolkit, not a replacement

CNCs do not solve every woodworking problem, but they can be a terrific addition even to a small woodworking shop. Have you ever looked at a traditional cabinet and admired the carvings that help to make it so cool? Ever wished that you could add that sort of detail to projects that you build — but you don't have the time or desire to learn the carving techniques?

A CNC can add those embellishments to your work. Same thing with adding inlay to a project, or the cribbage board holes I mentioned earlier, or any number of other intricate tasks that are very tedious to do without it. Don't mistake this for being lazy: You, as the woodworker, are still doing the bulk of the building, cutting, sanding, and whatever else is involved. You're just letting the CNC cut down your time by having it do the inlay work.

And that is an important point. A CNC can do some things for you, and do them exceptionally well, but it can't do everything. You can't plop an acorn on the table, turn it on and come back to a completed dining chair. At its most basic, woodworking requires cutting and shaping wood so that you can assemble those parts to create a project of some sort. Your skill, creativity, ideas, and effort will still be the key to your woodworking success. No matter what, there will always be details to be addressed, hardware to be mounted, parts glued and clamped together ... to say nothing of sanding and finishing. Your skills and knowledge are still essential. The CNC will not replace you. It's just going to make your project a lot less tedious.

Don't let your fear of CNC routers constrain you: Embrace the future of woodworking

Given that I'm a woodworker, it's fairly obvious that building things from wood is something I love. Truthfully, though, there are some aspects of woodworking that I like more than others. If I can use a CNC to drill 121 holes in a cribbage board rather than doing it myself by hand, I will do so every time.

Back in the 1600s, Antonio Stradivari had a workshop in Italy where he created the most revered violins, cellos and violas in history. He is credited with making over 1,100 instruments by hand, with no power tools available, and certainly no CNCs. Well, I'm just going to clarify that it would be physically impossible for him to actually have made every part of every instrument by hand, by himself, in those 90 years. I'm not going to argue that he time traveled to get a CNC router, but he certainly had apprentices to help him. And those apprentices were the Renaissance's equivalent of today's CNC.

There are certainly some obstacles to getting started with a CNC. Cost is one (although they are certainly less expensive than an apprentice!). But like technology in general, the cost of small shop CNCs have been coming down and will probably continue to do so. There is also time required to learn how to use the software and the machine — but there is a similar learning curve to properly using a hand plane. Tool skills take time to master. And to me, the CNC is just another woodworking tool. It may be a tool you don't wish to own, but don't let the false arguments about CNCs being "cheating" give you grief. It's just not true.