Confused About Plywood, MDF, & Melamine? We Tell You How And When To Use Them

We may receive a commission on purchases made from links.

Shopping for wood often leads to questions. For example, what are those big rectangular flat panels at your big box store? What is the difference between plywood, MDF, and melamine — and why should you care?

In my career as a professional woodworker, I've used all three, so let me explain these differences and why they're useful to you. They can indeed look very similar — they're all large, flat panels of varying thickness — but I can assure you they are each used in specific ways that take advantage of their unique characteristics.

The commonality between all three materials is that they're man-made. This may lead you to the idea that these are modern inventions, but actually, a form of plywood goes back to ancient Egypt (I wonder what the square foot price was back then?). All three make use of wood or wood byproducts bound together with adhesive resin, usually a form of formaldehyde adhesive. The legendary plywood, with all its advantages and disadvantages, is generally made in panels 48-inches by 96-inches, and at varying thicknesses starting a 1/8", moving up in 1/8" increments. MDF and Melamine panels are 49- by 97 inches wide and long, with basically the same thickness choices as plywood. MDF can be purchased in much thicker sizes, but not from most home consumer stores. With all this in mind, let's go over the different tasks and projects that each material excels at.

What separates plywood from MDF and Melamine

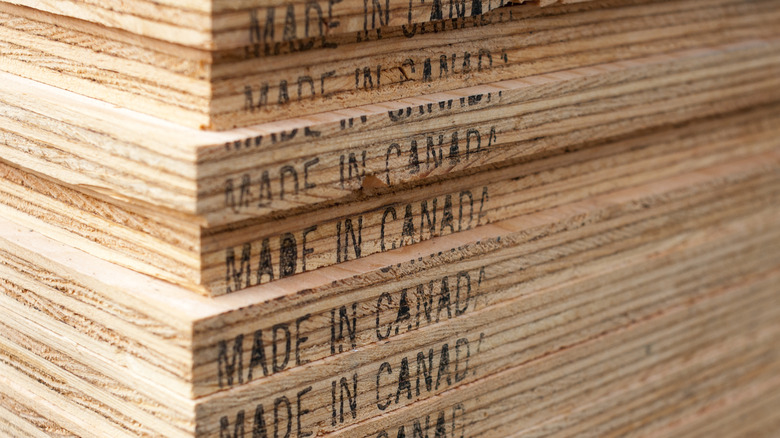

As the great granddaddy of the group, plywood is also the most diverse. There are so many versions of plywood that it's impossible to list them all, so let's just start by describing their most common characteristic. Plywood is made of layers (plies) of very thin wood (called veneers) glued together. The grain direction of the plies is alternated 90-degree to one another, creating a very strong and dimensionally stable product. One common question I'm often asked: Can you stain plywood? The answer is yes, you can do that — and more. It is a remarkably versatile product.

When it comes to plywood, there are almost always an uneven number of plies so there will be a center ply and two matching surface plies. This construction creates dimensional stability. Why is that important? Because wood is hygroscopic, meaning it absorbs moisture resulting from seasonal changes in humidity. It expands and contracts as it gains or loses moisture content. Large panels or wide cabinet doors of edge-glued solid wood will expand or shrink significantly, causing no end of problems in furniture and cabinetry. This is the primary problem in woodworking. Plywood solves it.

But that's not all. Its construction makes it exceptionally strong. That's why it's great for shelving. Plywood also comes with hardwood exterior veneers in various grain orientations, making it an excellent choice for cabinetry and furniture construction. Sure, most plywood comes with the drawback of ugly edges, but overall, it's a great material.

What is MDF board?

If you're wondering what MDF stands for, well, it's "medium density fiberboard," and let's just say it's a ubiquitous product. You'll find it in furniture, flooring, kitchen cabinetry, wall paneling, decorative molding and a host of other items. However, what is MDF board, and why is it so versatile?

Well, remember how I said hygroscopic wood movement is a big problem in woodworking? A defining characteristic of MDF is its stability. It's made from ground up wood by products mixed with wax and formaldehyde resins, compressed under pressure and heat. The resulting board can be cut and shaped with regular woodworking tools. It glues together well and holds screws, nails and other mechanical fasteners reasonably well. Its composite construction is both a blessing and curse. You can shape it in any way you wish, but the fact it is made from short fibers means small bits of it can easily be broken off. It lacks the strength that wood fibers found in solid lumber and plywood provide: That's also why it sags if used in long shelves. Otherwise, it is amazingly useful.

Some MDF panels are manufactured with hardwood veneers on its surfaces. MDF accepts paint well, providing a superior finish. You can apply your own decorative veneer, lay it up with plastic laminate (Formica), and combine it with any type of solid wood. That said, there are downsides. For instance, is MDF waterproof? Definitely not. It absorbs water easily and when it does, the fibers break down. Another problem is that while it is dimensionally stable, it lacks the strength of plywood.

Okay, so that's MDF and plywood: What is melamine made of?

Woodworkers like me will often simply order a sheet of melamine, which can cause a bit of confusion. Melamine, the compound, is an organic mixture that is transformed through polymerization into a hard plastic material. Your kitchen countertop may have a layer of high-pressure laminate (HPL) made from melamine called Formica. Melamine panels are covered with a thin sheet of melamine in its plastic like state, but in a low-pressure version (LPL). While not as hard and thick as the HPL plastic laminates used for countertops, it is a very durable protective layer. Melamine panels are scratch resistant and durable.

Melamine in this form can be colored to any hue or combined with a printed sheet of paper to add details like wood grain or a printed pattern (though big box stores options are usually limited to white, gray or black surfaces without patterns or textures). It's easy to see why melamine panels are so popular and versatile. To top it off, the surface already has a durable waterproof finish, with the caveat being that the exposed edges of these panels are not waterproof. However, you can find melamine tape for covering the edges of the panels, often pre-glued with a hot-melt adhesive. Use your clothes iron to apply it.

The core of a melamine panel is commonly particle board or MDF. While it can sometimes be applied to plywood, creating a very strong panel, this is expensive and not something you'll not find at consumer stores.

How to choose between plywood, MDF, or melamine for your DIY project

With your newfound knowledge of man-made sheet stock, how do you determine which one to choose, as you plunge boldly into your next DIY project? Let's start again with plywood. It is strong, stable and comes in a variety of types: Construction plywood, with its rough surface, goes under flooring, as sheathing on a new building, rough crates, and so on. Plywood with sanded surfaces can be used for more refined projects like toy boxes, drawer boxes, cabinet backs, doggie stairs and more. Waterproof or marine-grade plywood is used on boats or other exterior uses, like a basketball backboard. Plywood with hardwood veneer is used for making furniture or kitchen cabinets for the home. Regardless of the type, plywood is lighter than the other two options here, and stronger over a span.

MDF, meanwhile, is great for all sorts of interior projects: Storage cabinets, entryway cubbies, pet beds, side tables, any project that will be painted. MDF covered by hardwood veneer is commonly used in kitchen cabinetry.

Finally, melamine panels have the huge advantage of being covered with a hard durable plastic surface (no finishing required). It's used for all of the things mentioned above (not counting the construction grade plywood). And of course, these products can be combined together with each doing what it does best — say, a child's desk with a painted plywood casework base but a melamine desktop. Which just goes to show that there are no hard and fast rules about which of these products you can use for any project. I hope your future DIY adventures are pleasant ones.